Sand removal from wastewater can be reached in sand separation basins or centrifugal separators. They are designed to remove sand, gravel and other heavy solids characterized by sedimentation speed or specific weight considerably higher than the weight of the putrescible organic solids of the wastewater.

The sand traps are designed to:

- Protect the mechanical equipment from abrasion and wear phenomena

- Reduce the formation of sand deposits in the pipes, channels and ducts

- Reduce the frequency of cleaning interventions of the digesters, made necessary in consequence of to the excessive accumulation of sands.

ere are three main types: horizontal flow (rectangular or square), airy, or the vortex type. The airy model is the most used, to which it is possible also to combine an oil separation treatment, in order to obtain in a single basin, the following operations:

- Separation of heavy solids, essentially consisting of sand

- Separation of oily and grease substances with outcrop favorite by air insufflations

- Oxygenation of sewage with air blower, to avoid the arise of aseptic phenomena.

The separation of lightweight materials from the heavy ones is obtained by insufflation of air at low pressure by diffusers with elastic membrane; this causes a proper agitation in the upper layers of wastewater in the basin, so favoring the upwelling of oily substances on the surface. Therefore, the oils cluster in a superficial external area, delimited by a circular septum, while the sand grains settle in the lower zone of the basin, where the air agitation is practically absent.

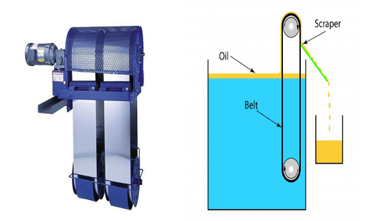

The evacuation of oily and grease substances is periodically made by a scraping system that directs the floated crust into the sump which is emptied periodically.

The extraction of sand is made by an air-lift that sends it to a special concentrator. The water that is separated from the sand is sent to the initial lifting sump, while the sand is periodically discharged in an appropriate collection bin.