Effluent Water Treatment

ROTATING FINE SCREENER

- Rotatory Fine screener is been installed at entrance of the influent to remove all floatable impurities in the water of size above 2mm.

- No bypass of screener is possible which directly reduces frequent maintenance works in pumps.

NEUTRALIZATION & COOLING TOWER

- Neutralization system is been supplied with pH sensor for complete automation and to give constant pH for effective biological conversion.

- Cooling tower is been supplied to maintain Biological temperature < 36 ° Celsius to maintain the system with maximum of active biots.

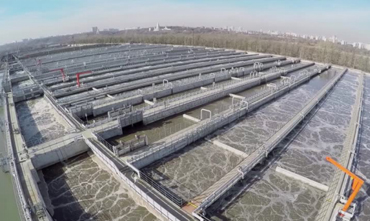

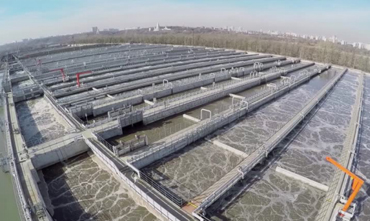

BIOLOGICAL TREATMENT TECHNOLOGY

- Biological is the heart of treatment process & efficient way to reduce the concentration of organic pollutants in waste water with simple automation.

- In Biological treatment we go with Extended Aeration Technique having higher retention period to treat all waters enters into the system

- To avoid septic condition in equalization tank we provide oxygen to maintain the water in suspension and as pre aeration step.

- Curved shaped biological tank design ensures uniform flow & mixing

- With Expertise design and complete automation on pH & DO we maintain & operate the biological system efficiently.

- To maintain optimum temperature for effective biological growth cooling tower is been supplied.

ACTIVATED SLUDGE TREATMENT

- Activated sludge systems are suspended-growth type and most widely used and efficient treatment system.

- We design the system to treat almost every wastewater influent as long as it is biodegradable to ensure this we go with nominal retention time required for the biot to react & convert incoming pollutants.

AEROBIC DIGESTION

- Activated sludge system run effectively with the presence of oxygen for the microorganism to respire, so atmospheric oxygen is been utilized and pumped into the biological system to keep the biots active and in suspension.

- 2 mg/L of oxygen concentration is mandatory for healthy growth of microorganism hence the oxygen is been diffused as fine bubbles in to the tanks in order to reach each & every microorganism in the system.

- Flow makers is been installed to maintain the water in suspension and to nullify the dead zone. It enhance the efficiency of the process and high conversion occurs.

SLUDGE DEWATERING SYSTEM

- Installation of Belt press with complete Automation ensures no manpower requirement for operating the system.

- Effective sludge capturing achieved by continuous washing of belt & Self cleaning nozzles.

- Maximum of 25% concentration of solids & 70% moisture achieved.

- Minimal maintenance required & nil stoppage for cleaning keeps the system in continuous operation.

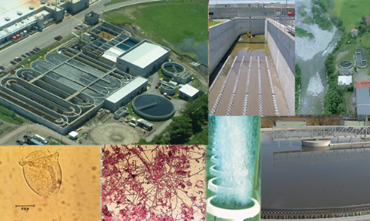

SEDIMENTATION PROCESS

- Clarifier is of different shapes but we go with conventional type circular clarifier in which removal of the accumulated solids is effective with scrapers rotating around the central axis of circular tank.

- By designing nominal retention time for clarifiers we have higher settling area by which Turbidity < 10 NTU is easily achievable

FILTRATION TECHNOLOGY

Separation of suspends from water is achieved through filtration using media. The process is differentiated with the usage of media.

- Pressurized Sand Filter (PSF) (Sand media)

- Activated Carbon Filter (ACF) (Carbon media)

- We perform effective backwash using blowers which removes all the filtered impurities and render quality outlet .

MEMBRANE TECHNOLOGY

We are into wide range of membrane technology for treating waste water with high pressure, low pressure & submersed type.

- Submersed MBR Technology

- Bio pulse MBR Technology (External)

- Ultra Filtration Technology

- Reverse Osmosis Technology

- Brine Recovery Technology

When comes to ZLD installation filtration system is designed to incorporate all the backwash flow from each system and delivers the required flow at 20hrs of operation.

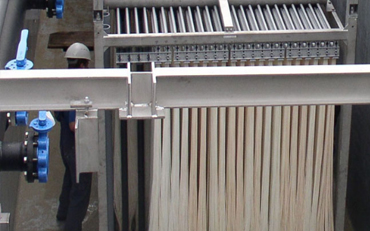

MEMBRANE BIOREACTOR

- MBR modules are like Extended Biological system which can handle Biomass concentration up to 12g and delivers complete removal of TSS in outlet.

- It can replace Clarifier, Quartz filter & Ultra filtration which can save lot of space with providing same quality of effluent.

- We have 2 types of MBR system

- Submersed MBR System

- Bio pulse MBR System

ULTRA FILTRATION

- We Design high reliability Ultra Filtration System using multibore technology which can handle high polluted water and run smoothly.

- We provide with coagulant dosing in UF feed for better removal of suspends and reduce the pressure build up.

- We operate with higher backwash flux to ensure complete removal of fouling in membrane and to have long life run.

ION EXCHANGE TECHNOLOGY

- Calcium & Magnesium are the main fouling which affects RO Membrane.

- Resin filtration is been designed for complete removal of calcium & magnesium ions from waste water with easy operations & minimal maintenance which favours high recovery in RO for long run.

- Plugging and drain of resin.

DEGASING TOWERS

- Decarbonising towers is been supplied with blowers & pH sensing element for automation, by which bicarbonates are stripped as carbon dioxide gas.

- Membrane damage due to pressure build up in RO is been completely avoided and increases the membrane life time.

REVERSE OSMOSIS

- Effective RO design delivers higher recovery (96%) with lower energy consumption.

- Dedicated CIP skids for each stage maximize the operating hours by reducing the cleaning time.

- Making complete automation with instruments & VFD for HP pump can optimize the recovery based on running condition.

BRINE RECOVERY PLANT

Brine recovery plant are similar to RO plant where we use ion selective membrane.

- Segregation of ion is been achieved based on valency .

- Plant is been designed for complete removal of divalent ions ( eg: SO4, Ca, Mg, etc..)

- Low running cost and high recovery of brine is achieved.

REJECT MANAGEMENT TECHNOLOGY

The high conductivity reject is subjected to Evaporation and salt recovery process to accomplish ZLD.

- Multi Effect Evaporator (MEE) where concentration of effluent achieved by applying steam.

- Crystallizer where Glauber salt is been recovered by retaining temperature below 10° Celsius.

- Agitated Thin Film Dryer (ATFD) where reject is been fully converted as salt.

ZERO LIQUID DISCHARGE PLANT

Zero-liquid discharge (ZLD) is a water treatment process in which every drop of water is been purified and recycled, leaving salts as residue at the end of the treatment cycle.

INDUSTRIAL WASTE WATER TREATMENT