One of the fundamental parameters for the water for industrial use is related to the hardness, defined as the sum of the ions Ca++ and Mg++, present in it. Hard water implies problems of fouling due to the carbonates formation and major problems also for the production.

For example in the case of textile industry, the hardness should be the lowest possible, to avoid the following phenomena in the various stages of processing:

Washing:it causes a considerable increase of the required quantity of detergent

Bleaching:it reduces its efficiency, creating an hard hand on tissues and making more difficult the next dyeing step; also it causes the yellowing of the tissue

Dyeing:it causes an increase of the required quantity of dyes, as it causes a partial precipitation. Furthermore, the presence of bicarbonates can damage the fiber and reduces the rubbing fastness of the colours.

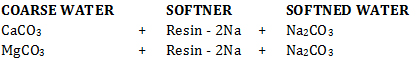

The softening is normally made by a strong cationic resin, regenerated with sodium chloride. The active groups of the regenerated resin are saturated with Na++ ions, which are exchanged with Ca++ and Mg++ ions of the water to be treated. The salts in the water undergo the following reactions

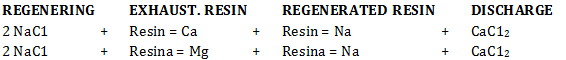

During the exhaustion phase, the resin passes progressively from Na form to the Ca and Mg form. A regeneration cycle through the following reactions is necessary to restore the resins to their initial exchange capacity:

Usually the softener filter involves the use of pneumatic valves and appropriate instrumentation, in order to manage all the cycles of filtration and backwashing in completely automatic mode.